Language & Region

Qioptiq

Qioptic | PLANNING TRANSPARENCY

Complete mapping of production planning processes with simultaneous process harmonization and optimization

Implementation Highlights

- Standardized production planning processes mapped across plants

- Prompt delivery of all components for the production order

- Reduction of buffer times through finite capacity planning

- Reduced setup effort through optimized planning

- Setup-optimized production planning

- Optimal use of capacities

Challenges

- Increasing complexity in terms of product variety, parts list depth, machinery & employees, replanning by customers

- Faster response to requests and changes

- More transparency on the order network and resource utilization

- Requirements cannot be met by planners or can only be met with a great deal of time

Project goals

- Uniform processes and simple, cross-plant handling

- Increase of delivery reliability

- Reduction of processing times

- Reduction of stocks

- Efficiency increase

Qioptic

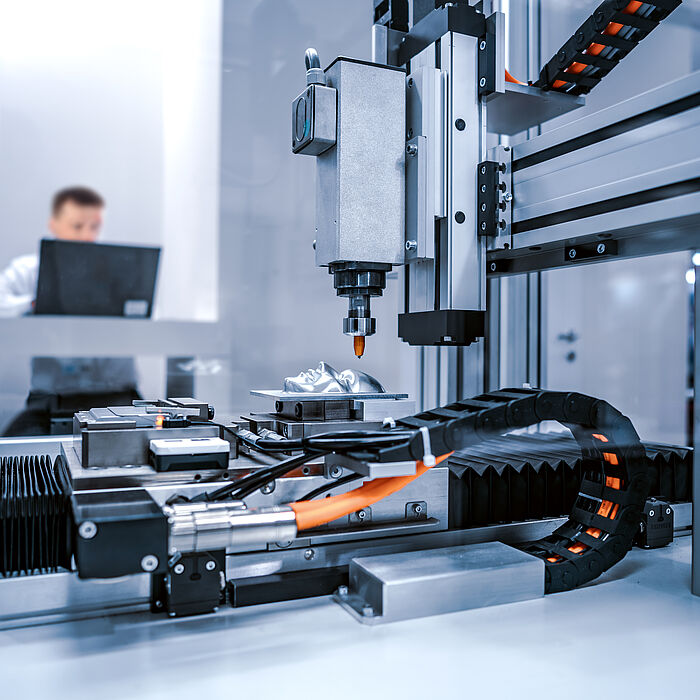

- Industry: Optics

- Products: Development and production of photonic products, complete solutions and applications in the fields of industrial manufacturing, medical and life sciences, research and development, defence and aerospace

- Web: www.qioptiq.de

- Project: Introduction of SAP SCM APO in several plants

- Implementation partner: CONSILIO GmbH