Language & Region

Stable production plan

Add-on solution for stable production planning in PP/DS

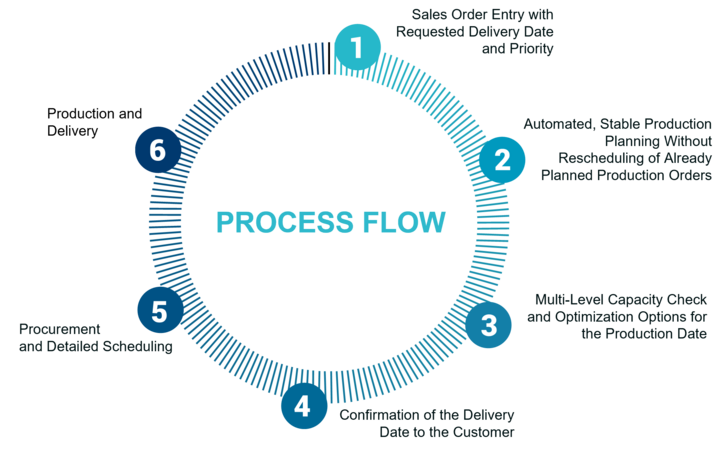

The add-on solution for stable production planning is aimed at industrial manufacturers whose goal is to make production process planning more flexible and at the same time more efficient. The integration of customers and suppliers into the supply chain is a fundamental prerequisite for this. Furthermore, detailed planning must take into account changes at machine level. With the integration of the extended production planning PP/DS into the SAP HANA platform and the stable production plan, a fast and powerful solution is available.

Goals and functions: Stable production planning prevents frequent replanning

- Mapping of make-to-stock, make-to-order and project manufacturing processes

- Scheduling of new orders into free capacities

- Ensure adherence to schedules, orders already scheduled are not rescheduled

- Stabilization of order sequences, changes in the short term only in exceptional cases

- Scheduling of complex job structures automated or inactive simulation

- Automated scheduling taking into account capacities, component availability and customer priorities by using the PP/DS optimizer

- Cross-plant planning

Advantages: Planning stability in medium-sized production

- Implementable stable production plans with timely fulfillment of customer requirements while maintaining quality standards

- Optimized order sequencing and resource utilization with simultaneous reduction of resource requirements through improved production planning and consideration of alternative machines

- Inclusion of capacity, material and tooling availabilities as well as personnel qualifications in production and detailed planning

- Provision of sophisticated planning functions

- Calm, capacitive, smoothed production