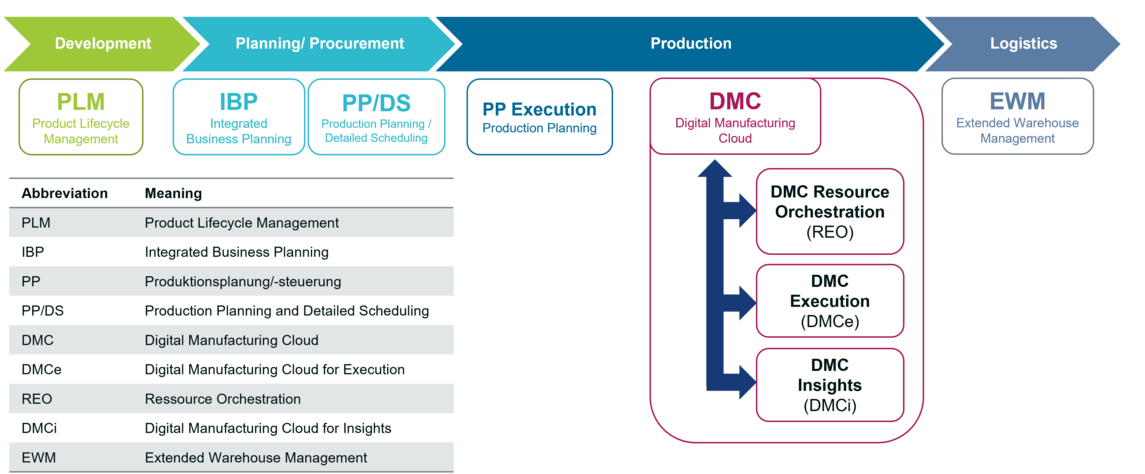

Cloud, IoT, Machine Learning, Predictive Maintenance, Big Data and Robotics are the images of Digital Transformation. These technologies are key elements when it comes to making a company fit for the future. To benefit from them, they must be integrated into the supply chain. Only then will the company benefit from increased data transparency, know what makes the market tick, and be able to react early to changes on the supply and demand side. With the Digital Manufacturing Cloud (SAP DMC), SAP is bringing Industry 4.0 to the store floor and into the cloud. To this end, it is developing new applications and technologies and is considered a trend-setter in terms of Industrie 4.0 functionality. CONSILIO as a holistic consulting company covers the complete value chain with its services - from development to delivery and service.

NEW TECHNOLOGY, NEW SYSTEMS

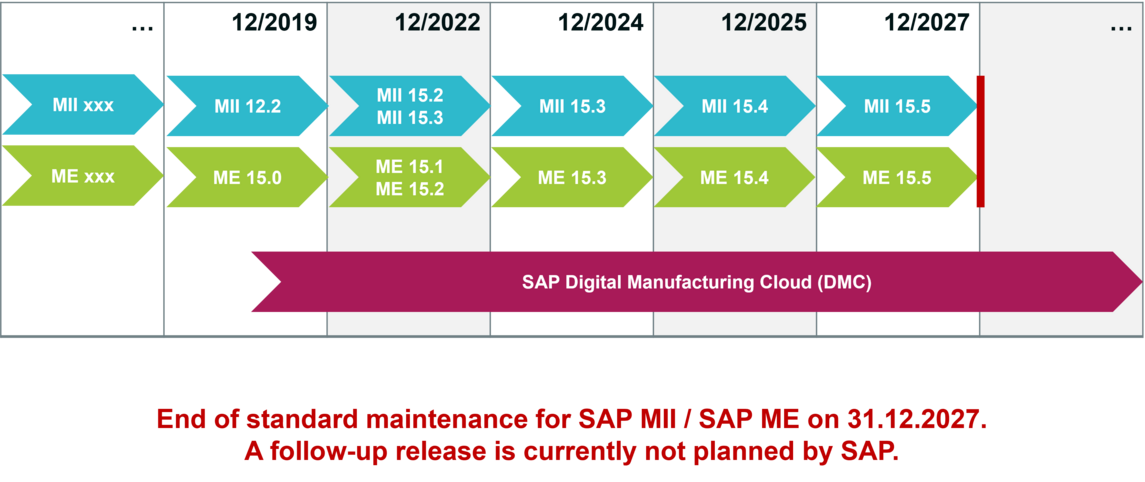

Although SAP currently has products in its range with SAP MII and SAP ME that offer a comparable scope on-premise, these will be discontinued on December 31, 2027 and will not be further developed until then. There are two reasons for this. With its software-as-a-service (SaaS) approach, SAP can respond more quickly to customer needs - in other words, offer functions more quickly. On the other hand, the constantly growing demands on a wide variety of systems require new architectures in order to be permanently efficient. Local system landscapes certainly give companies internal control over data protection and data security, but they are demanding and expensive to scale. Cloud solutions, on the other hand, benefit from the high scalability, service models and cost savings of cloud computing that cannot be realized with data centers in the short term. SAP DMC as a cloud MES solution is also operated as SaaS. This means no maintenance costs for the user and, in parallel, the system is automatically supplied with updates four times a year. The result: continuous further development of the system and lower operational costs.

What makes the DMC special?

The SAP Digital Manufacturing Cloud (SAP DMC) is a central, cloud-based MES system for the manufacturing and process industry that can be used to orchestrate, execute, and monitor processes along the entire value chain in the spirit of Industrie 4.0. The solution connects all top-level business systems with assets on the shop floor. This gives users global visibility of data across all plants. Hybrid system landscapes can thus also be mapped with DMC as the central element. The DMC thus represents a bridge between the individual layers on the one hand and between the processes on the other.

Three modules

The SAP Digital Manufacturing Cloud (SAP DMC) is a central solution for the process and manufacturing industry that can be used to orchestrate, execute and monitor processes in the sense of Industry 4.0, even across company boundaries. Essentially, the solution comprises the following components: Digital Manufacturing Cloud Execution (DMCe), SAP Resource Orchestration (REO) and Digital Manufacturing Cloud Insights (DMCi).

Production: DMC Execution

Resource Orchestration (REO) planning tool

The cloud-based planning tool can be used to manage order-related resource utilization and monitor events on the shop floor.

- View information about resource utilization and the current production situation.

- Realistically match machine and personnel availability to supply and demand

- Visually highlight prioritized orders or operations

- Release, schedule, or reschedule individual operations

- Detailed information on employee work schedules - including availabilities, skills, shifts and certifications

Analytics: DMC Insights

The Analytics solution DMCi represents a data-driven performance management. The end-to-end transparency created in this way enables in-depth insights into production. The module provides KPIs (Key Performance Indicators) and visualizes analyses from real-time information in configurable dashboards. Production data from data sources such as SAP S/4HANA, SAP MII on-premise or non-SAP systems can be merged, evaluated and made available in the cloud.

- Data-driven manufacturing performance management

- Uniform, comparable and company-wide standardized KPI's for performance analysis.

- Artificial intelligence for continuous improvement of production efficiency

- Real-time data collection and real-time analysis

Summary

As a SaaS solution, SAP DMC can be integrated directly into SAP S/4HANA or an existing SAP ERP system. Through the integration, production data including the available resources - such as machines or employees - can be planned on the store floor and all follow-up processes can be triggered. The cloud-based MES system also creates end-to-end transparency across sites, even at a global level, about plants, selected workstations or individual machines. DMC's analytics capabilities, combined with KPIs, artificial intelligence and machine learning (ML), promote rapid decision-making by providing real-time reports in the cloud. The result is consistent and transparent manufacturing processes across system and company boundaries.