Language & Region

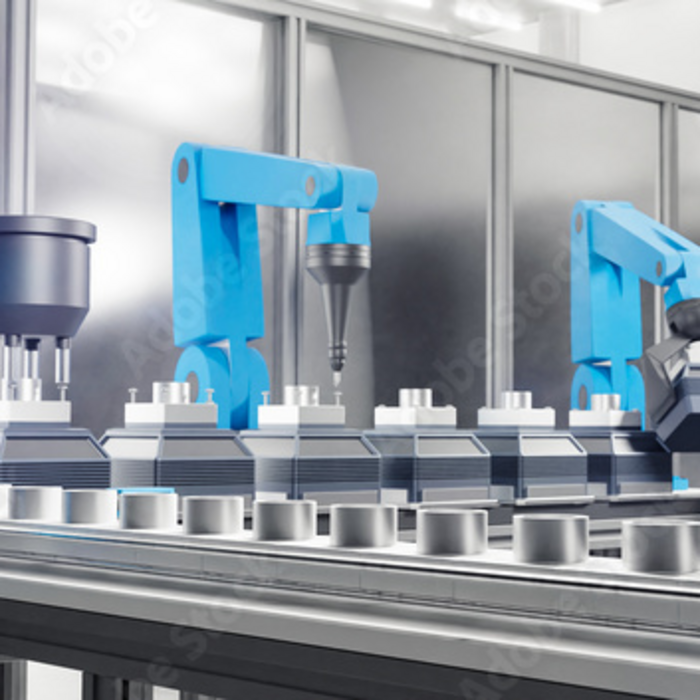

Diehl Controls

Production planning with embedded PP/DS under S/4HANA

Introduction of cross-system finite planning with S/4HANA

Implementation Highlights

- Introduction of cross-system finite planning with S/4HANA

- Introduction of bucketfinite material planning

- CONSILIO solution for maintaining alternative manufacturing versions via finite MRP

- Successive production launches instead of big bang

Employees

million euros turnover

million electronics per year

Continents

Project goals

- Replacement of the previously used production planning system

- Creation of integrated finite planning in S/4HANA

- Introduction of bucket finite material planning

Characteristics of the Project

- Use of alternative production versions in optimisation: Alternative production versions were not abolished, but were to remain finite in the optimiser.

- The go-live of the PP/DS functionalities took place via pilots in successive production launches per line or production area and not in a big bang - across countries at different locations.

- Although purchasing was taken into account with its access situation in PP/DS optimisation, it is still planned in ERP. The reasons for this are the complex scheduling agreement processing and call-off creation.

- Technical challenge: In the case of complex, cross-order connections across different batches, the use of fixed pegging simplified the process and removed complexity from the optimisation.

Benefits of the new solution

- Cross-system, finite planning with S/4HANA

- Utilisation of PP/DS functionalities for finite bucket planning

- Extended comment function on the production order in the detailed planning board

Diehl Controls

- Industry: high-tech

- Business area: Diehl Controls is one of the world's leading suppliers to the household appliance and HVAC/R industries – from development and industrialisation to high-tech production.

- Products: Scalable electronic systems and electronic products used in heat pumps, washing machines and many other end devices.

- System landscape: S/4HANA 2020

- Implementation partner: CONSILIO GmbH

Further information

Specialist area Production

Specialist area Production

We implement future-proof and agile solutions customised to your company.

S/4HANA Manufacturing

S/4HANA Manufacturing

Digitise your production with the help of SAP S/4HANA.

SAP PP/DS & ePP/DS

SAP PP/DS & ePP/DS

Production planning: Integrated optimisation & detailed planning in S/4HANA