Introduction of the SAP cloud solution Integrated Business Planning (IBP)

Transparency regarding demand, stocks and capacities along the supply chain

Implementation Highlights

- Significantly increased transparency along the entire supply chain

- Group-wide, precise response to changing market situations

- Modern planning algorithms and improved system support for planners

- Cost savings due to fewer planning errors and missed opportunities

- Successful implementation project despite 100 percent remote work

Initial situation

As part of its digitalisation strategy, TEEKANNE decided to introduce the SAP IBP planning software. The company wanted to use it to improve existing processes and tap into further strategic potential in order to ensure greater transparency in the Group-wide supply chain. Harald Liedtke, Head of Digital Transformation (CIO) at TEEKANNE, and Christoph Habla, Head of IBP at CONSILIO, had overall responsibility for the project.

The challenge

By networking sales, production and purchasing, the topic of supply chain planning is a prime example of cross-departmental and cross-location collaboration with major changes to previous processes. The departments involved and their planning topics are brought together via the central IBP tool with a standardised database in the sense of a single point of truth. Change and expectation management are regularly underestimated in such projects and tie up a large proportion of internal resources.

Project goals

- More efficient planning process with better results, faster processes and improved utilisation of available resources

- More transparency in the Group-wide supply chain

- Greater flexibility in responding precisely to changing market situations

- Improving the future viability of processes and tapping into further strategic potential of digitalisation

- Conversion of the company to centralised supply chain planning in SAP IBP within two years

Project process

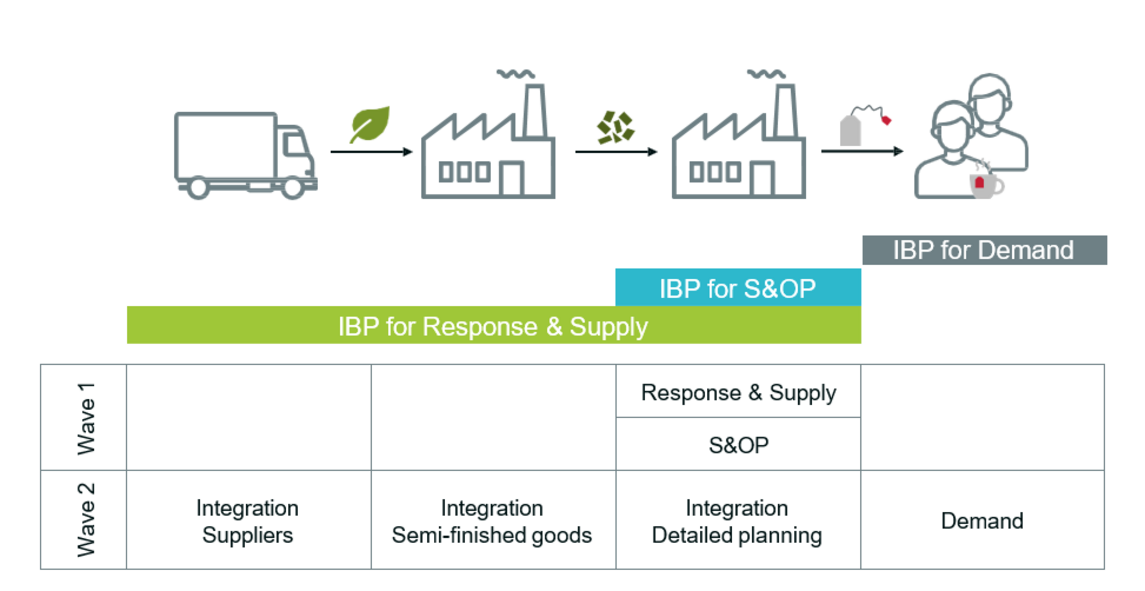

The project was implemented in two waves: In the first wave, the focus was on the supply planning of the production network for the end products. The preliminary product stages were not integrated at this time, nor was demand planning, which was still mapped using the non-SAP system TIA.

Supply planning for the production network comprises seven plants across Europe, where capacity should be planned in addition to production and distribution. It takes place once a month and supports the S&OP process. The results of the supply planning are fed back into the ERP as planned independent requirements and form the basis for the MRP run and detailed planning.

These values describe which end products are to be produced in which plant, in which quantities and in which month for a period of 18 months. This data is therefore a constrained forecast - i.e. a realistic production programme based on the company's operational capabilities.

The product preliminary stages were added in the second wave. In addition, demand planning with the external TIA system was to be replaced by IBP. Demand planning is carried out at TEEKANNE in the individual countries for the end products. In addition to statistical forecasts and customer forecasts, the planning of key account managers and budget planning are also incorporated here.

Planning with IBP is underpinned by data from SD, which provides all prices and conditions as well as the customer hierarchy. This allows realistic pricing to be implemented and the required quantities per plant and material to be determined by disaggregating the sales.

Summary of the case study

The introduction of SAP IBP guarantees TEEKANNE significantly increased transparency along the entire supply chain, as well as greater flexibility in responding to changing market situations.

Modern planning algorithms and improved system support for planners enable an efficient planning process with better results, faster processes and improved use of available resources.

This also avoids costs resulting from planning errors or missed opportunities. TEEKANNE is thus well prepared for future challenges.

![[Translate to English:] TEEKANNE](/fileadmin/_processed_/3/2/csm_teekanne-02_3f2f089409.png)