The SAP S/4HANA solution for availability checking advanced Available-to-Promise (aATP) combines the ease of use of the ERP solution with the extensive range of functions offered by SAP APO Global ATP.

In addition to many additional functionalities that are not available in the ERP solution, the aATP scores with its increased user orientation, which is partly due to the new Fiori interface. The application setup is also simplified in many parts. Below is an overview of some of the important features included in aATP. Since the feature set of the on-premise solution differs from that of the cloud, the following explicitly discusses the on-premise solution.

Contingency (PAL)

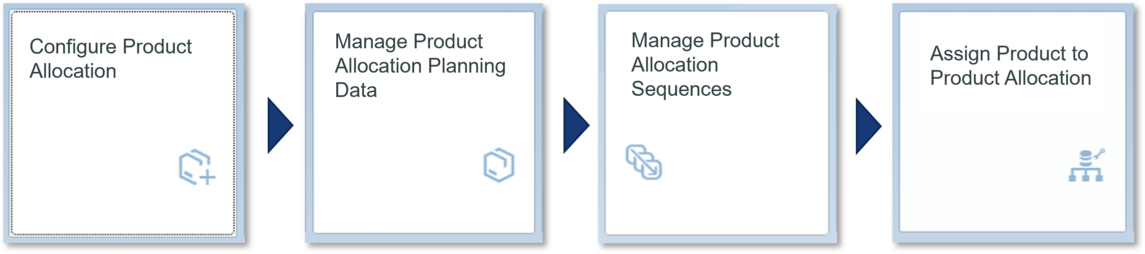

Allocation is understood as a customer- and/or capacity-related restriction of material allocation per period to pre-planned quantities. The basic functionality is mapped via four Fiori apps, which handle all functionalities from configuration to product allocation:

In addition, there is a graphical analysis app with which the quota objects can be monitored and over- and shortage situations can be detected and adjusted at an early stage.

In contrast to the ECC solution, aATP can be used to allocate both before and after the product availability check. For example, customer-based quota allocation can be performed before the ATP check and capacity quota allocation can be performed after the ATP check. The allocation plan data and material allocations are normally uploaded and downloaded with Fiori apps, and a plan data creation is also possible in the background to automate the process.

Availability protection (SUP)

Availability protection is a new check type in the availability check for reserving available quantities for prioritized customer groups and/or organizational units. Here, availability protection objects are defined at material/plant level, such as a region (a country, a sales organization, etc.) at whose level available quantities are to be reserved for specific operating areas, customer groups or other freely selectable groups.

For example, Region A is assigned groups "Original Equipment" with priority 1 and "Trade" with priority 2. This vertical structure allows original equipment to always be prioritized over trade and be allowed to draw from trade requirements. However, the trade is not allowed to tap the stocks that are allocated to the original equipment.

Vertical allocation can be combined with horizontal allocation: In such a combination, several groups share the available quantities at one level. The quantities reserved for one customer are no longer available for the other customers on the same level.

The functionality of availability protection allows a filigree reservation of quantities in future periods, which was previously not possible in this form and granularity.

Residue processing (BOP)

Backorder processing is used to distribute available quantities to unconfirmed sales documents and stock transport orders, and to redistribute confirmed quantities between such documents. Compared to the ERP solution, the solution has become many times more comprehensive and now covers almost every conceivable requirement.

Groups of order items with different priorities are defined for processing. These cover the entire spectrum of documents, starting with those with the highest priority (winning) to orders where the confirmations are to be completely withdrawn (losing) in order to be able to distribute them to higher priority orders. The selection and sorting sequences can be defined by the user, so that a new sorting can be carried out flexibly for each run. If one of the defined rules cannot be implemented, another predefined alternative rule is used. Before implementation, the result can be displayed and evaluated in simulation mode.

Product availability check (PAC)

The product availability check determines whether a material can be provided in the desired quantity on a given date, determines an alternative date if necessary, and sets the requirements for material requirements planning. In contrast to the ERP solution, simultaneous processing of several document items is possible here, which means a speed advantage for large document volumes. To further increase speed, the ATP-relevant requirements and reservation tables in S/4HANA can be kept in SAP liveCash.

Alternatives based confirmation (ABC)

Alternatives-based confirmation allows plant, storage location and/or product substitution depending on substitution master data. Based on this substitution master data, which is linked to each other and has predefined validity periods, a substitution strategy is run through. The replacement types "plant", "storage location" and "product" can be combined in one strategy. The replacement master data controls the replacement process, exclusion and termination criteria, etc.

Typical use cases include scenarios where one material is replaced by another over time or seasonally, or where a material is to be supplied from other locations if it is not available at one location.

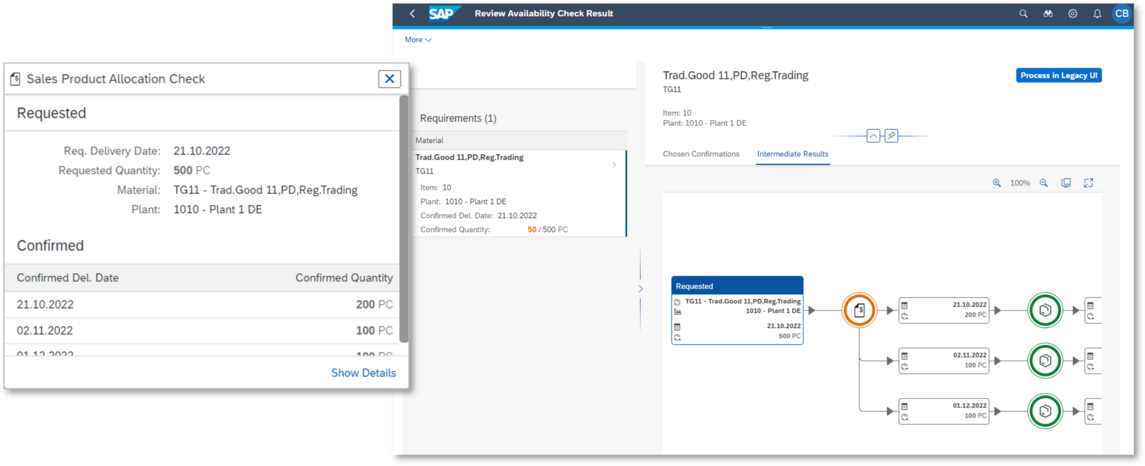

Display of the ATP test result (RACR)

This function displays the availability check result across all items in one screen with a drilldown option. For detailed analysis, it is possible to jump to detailed screens - for example, to the allocation, product or location substitution. The availability results of an order can be accepted in one step instead of step by step per item as in the ERP environment.

Release for delivery (BOP/RFD)

For short-term quantity redistribution between sales orders shortly before delivery creation, SAP offers a Fiori-based delivery creation monitor as part of the advanced ATP. In a first app, the user defines his worklist via relevant organizational units and selection deadlines, and in a second app, the actual monitor, the confirmation quantities in the sales orders are adjusted and deliveries are created at the same time. Possible interim changes in the sales order during runtime are taken into account in the Fiori app.

Confirmation based on access generation (SBC)

Despite searching in other plants/storage locations and checking alternative materials, it can happen that an order item cannot be confirmed. For this case, a solution has been available since Release On-Premise 2022 that generates planned orders, purchase requisitions, or stock transport requisitions as requirement cover directly from the availability check, depending on the requirement. For the generation of receipts, the source determination in PP/DS compares requirements and receipts on all BOM levels according to the defined planning procedures and calculates a possible confirmation date from this. The order item is then confirmed on this date.

Confirmation based on receipt generation is also possible in combination with allocation at the level of the end product.

Summary

In addition to the functionalities already included in the ATP solution, advanced ATP in S/4HANA contains some innovations that make a material availability check more filigree and flexible. Although the aATP is integrated in S/4HANA, it is subject to licensing. The question of whether aATP is right for your company should therefore be examined with the support of an experienced partner.