Predictive Material and Resource Planning (pMRP)

Identify capacity problems with pMRP and solve them early in the planning process

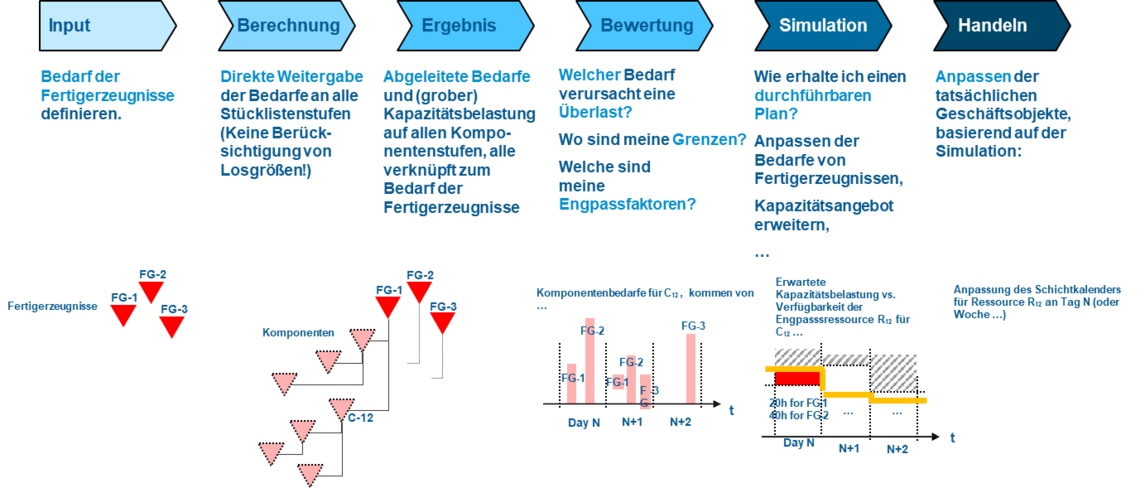

Predictive Material and Resource Planning (pMRP) is a new SAP S/4HANA Cloud product for simulative and interactive long-term demand planning. The aim is to identify potential capacity problems as early as possible on the basis of a predefined demand for finished products and to identify possible solutions. The simulation calculates the demand for components, purchased parts and resources and thus provides production planners with a basis for decision-making in the event of changed conditions, e.g. with regard to demand planning, deployment plans, prefabrication or make-or-buy decisions.

Benefits of the pMRP

Forward-looking material and resource planning provides production planners with a basis for making decisions when conditions change, e.g. with regard to requirements planning, deployment plans, prefabrication or make-or-buy decisions:

1. Material Forecasts:

Checking the feasibility of forecasts including availability of capacities and suppliers

> Prevention of stock-outs during marketing campaigns

2. Capacity planning:

Adaptation of shift programs or expansion of machine capacity, early communication with employees and production

> Preparation for expected production volume

3. Strategic procurement:

Renegotiation of contracts due to economies of scale

> Reduction of purchasing costs

4. Operational procurement:

Derivation of future component requirements

> Creation of medium and long-term overview on component and purchased part level, improvement of cooperation with suppliers

Range of functions

Process & Data Flow

To create a simulation scenario, the master and transaction data is copied from the operational S/4 environment into a separate pMRP planning area. The most important objects here are materials, bills of material, work centers & work schedules, production versions and planned independent requirements. Instead of pre-planned requirements, sales orders can also be used aggregated in buckets. The predictive MRP then calculates the demand for components and purchased parts as well as the capacity utilization based on a simplified image of the data. Any changes made, for example to capacity availability or pre-planning requirements, can then be transferred back to the operational environment.

Difference between pMRP and long-term planning in ECC

- User Interface

The pMRP is a pure cloud product to be used in conjunction with FIORI. A use in the classic GUI is not supported.

- Speed

Long-term planning is based on the classic MRP, which still comes close to the speed of the new MRP for small data volumes. For large data volumes, long-term planning takes considerably longer than with pMRP. The pMRP can calculate changes in demand much faster through the bill of materials and thus determine component and capacity requirements.

- Master data

Long-term planning used the same master data as operative planning. However, it was also possible to use special long-term planning master data. In pMRP, the master data must first be loaded into the planning scenarios and, according to SAP, is still compressed/simplified, e.g. lot sizes cannot (yet) be taken into account. Likewise, the use of special master data is not planned for some scenarios.

- Capacity planning / evaluation

The capacity evaluation in long-term planning only shows that an overload may exist and which planned orders per period cause the overload. In this case you have the option of dispatching planned orders or deallocating them. The pMRP goes one step further. In the case of an overload at component level, it can display the demand for finished products that caused the overload by means of the pegging relationships. For example, the overload can be eliminated by reducing the planned independent requirement for finished materials.

Another fitting aspect is that pMRP allows the capacity of workstations to be increased and reduced in simulations. For example, to simulate potential failures or short-term capacity expansions. This was not possible in long-term planning. Only specific routings and bills of material could be used there.