Production Engineering & Operations (SAP PEO)

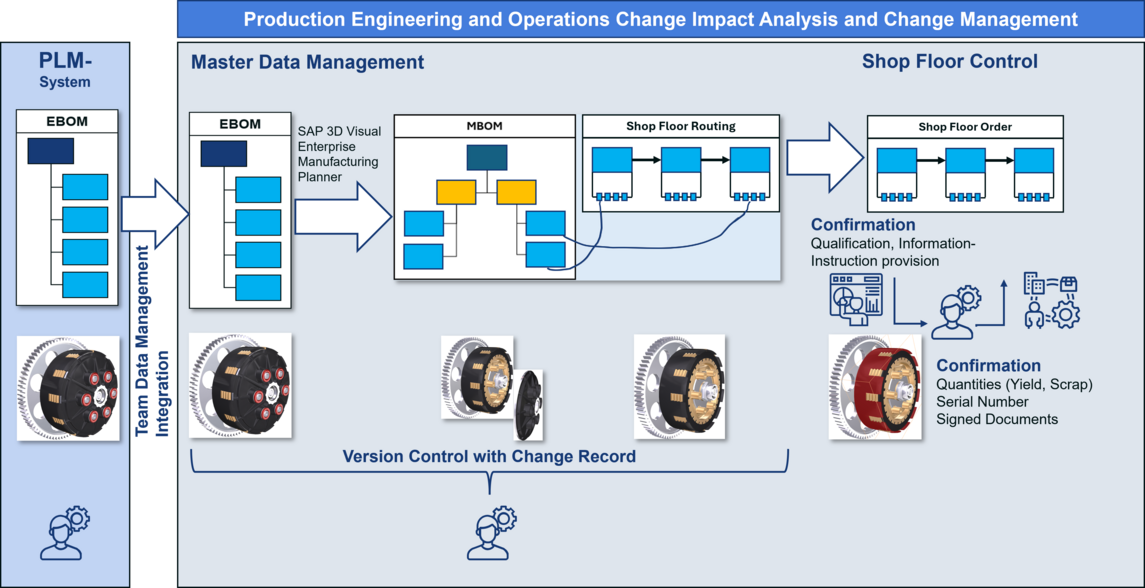

SAP PEO links development and production in the company. To do this, it links the technical bill of materials for development (EBOM) with the production bill of materials (MBOM). The result is the digital twin.

The SAP PEO platform is aimed at industries that are involved in discrete manufacturing in the broadest sense. Intelligent networking of processes such as order management and production control (Production Order Management & Control), work execution (Operations), and tracking and quality assurance (Tracking & Genealogy) enables an integrated, efficient, and, above all, economical process chain from product development to production to be realized - even with batch size 1.

In detail, this means that PEO consolidates the manufacturing process from engineering to production, while giving users all the tools they will need to handle sophisticated and complex products. This includes functions to model the manufacturing process in detail, or to give guided instructions to workers and record the progress of manufacturing. Due to the high flexibility of the solution, it is also possible to incorporate design changes once the manufacturing process has already started.

If you take a closer look at the business processes of manufacturing companies, you will notice the large number of heterogeneous system landscapes consisting of various PLM, QM, MES and ERP software solutions.

As a result, production efficiency suffers significantly. This is because engineering and order change processes cause high process and quality costs due to insufficient integration and the associated complex bidirectional system interfaces. This is especially true if one takes into account the increasing product diversity due to Engineer-to-Order (ETO), Make-to-Order (MTO), Configure-to-Order (CTO) and Assemble-to-Order (ATO), which is typical for special machine manufacturing and its very complex products with a comparatively long lead time. This presents users in particular with the difficult task of establishing solid change management that meets their own and the customer's requirements.

Take advantage of SAP PEO

- Consistent data management and better end-to-end process to manufacturability

- Clearer understanding of the impact of changes on customer orders or manufacturing processes

- Traceable linkage of processes in the company

- Better understanding of production processes from design to real time

- Faster performance of processes

- Lean and optimized processes with a workflow tool in the background

- Easier traceability of processes through workflow control

- Versioning of parts lists and routings

- Digital twin (EBOM & MBOM)

- Clear overview of the processing of individual operations in production

- Simple serial number processing in discrete manufacturing within production orders

- Effective control of the manufacturing process from the administration & design viewpoint

- Transparent overview of resources

- More efficient resource planning in production or during order assignment

- Faster and better reaction to interruptions or quality problems

SAP PEO functionalities

The life cycle of a product begins with the EBOM - Engineering Bill of Materials, a type of technical bill of materials that depicts the planned product. Once the product is technically developed, it is handed over to production in the form of a manufacturing bill of material or MBOM. Three tools for the handover-to-manufacturing process help to manage the reconciliation of the engineering bill of material with the manufacturing bill of material: SAP Product Structure Synchronization (PSS), SAP 3D Visual Enterprise Manufacturing Planner (3D Vemp) and Intelligent Enterprise Handover, which also combines functions of the first two tools.

- Until now, SAP's core system did not offer a reasonable interface for data transfer to SAP PP - which is why users had to deal with lists without 3D models. S/4HANA, on the other hand, is equipped with the new TDMI interface (Team Data Management Interface). SAP PEO thus understands all common CAD and PLM systems, such as those from Siemens, Solidworks, Windchill or Teamcenter.

In this way, for example, engineering parts lists can be enriched with 3D models and additionally with PMI data (Product Manufacturing Information) such as tolerance specifications or spot welds and transferred to the SAP core system. This enables very granularly resolved complex workflows that are linked to 3D BOMs. An integrated QM module also provides inspection during production

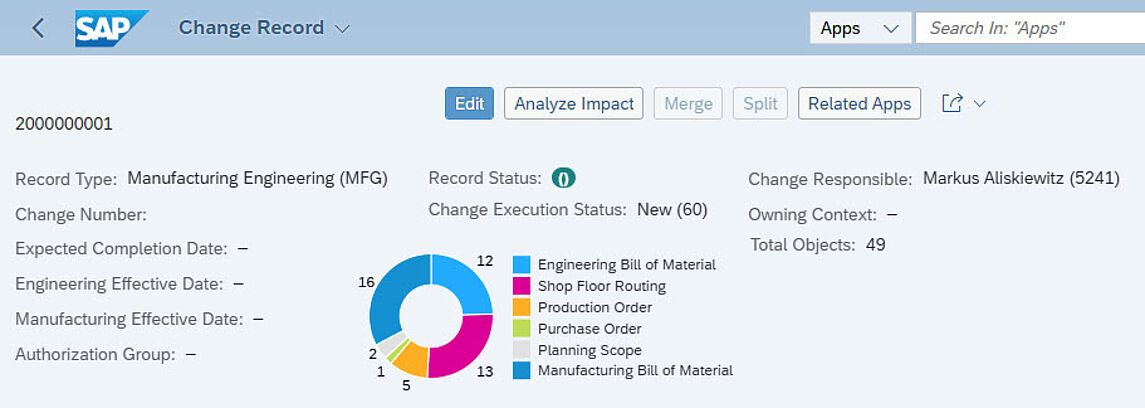

- Impact analysis supports manufacturing in quickly and efficiently determining all manufacturing objects that are potentially affected by a change - such as routings, bills of material, production orders or purchase orders.

- In engineering, impact analysis can be used as a where-used list to see where an attached object, such as a material, is still being changed. In this way, parallel changes can be identified at an early stage and, under certain circumstances, changes can be merged.

- The Change Record bundles the SAP objects to be changed and thus forms the central link in the PEO. The Change Record workflow ensures that every processor, be it the requester, engineer or the person who has to approve the change, is always aware of what is currently being changed and what the current status of the changes is.

- The change record historizes changes and decisions so that in the event of future queries, it can be quickly shown why a change was made

- Since the FPS02 release in spring 2021, the new Change Record can reuse the proven Process Route instead of having to use Flexible Workflows. The Process Route provides more functionality and automation, allowing end users to focus on what's important: Their work

For the entire SAP PEO functions, a variety of user-friendly applications are available in the system in the SAP Fiori Launchpad in addition to classic GUI transactions. On this basis, it is possible to implement and establish end-to-end processes with seamless traceability with regard to engineering changes. This provides designers, planners, production controllers, work planners and workers with a platform that accesses the same database.

- Operation activities are features that are predominantly known from MES software solutions. Production planners use them to represent individual production operations of a routing in multiple activities in order to significantly increase the level of detail.

- For example, you have full functionality compared to the familiar sub-operations from ERP. All aspects of a workflow, such as component assignment, work instructions, inspection characteristics, production resources/tools, documents, acceptances, qualifications and task managers can thus be assigned to operation activities

- Planning and execution of the production order are carried out in SAP PEO via FIORI apps specially designed for this purpose.

- Based on the stored qualifications, employees are assigned to the pending orders and their work lists are filled. In this way, it can be ensured from the outset that only qualified employees perform certain work or activities.

- Production monitoring provides the responsible employees with tools to analyze the manufacturing process for serialized products. For example, it documents which components were assembled or disassembled, which data was collected, and which problems were logged. This makes it possible to monitor every single operation activity related to a manufacturing order.

- An as-built report for assemblies based on the production order shows material and serial numbers and thus supports the analysis. Managers can see which materials (planned and unplanned) have been consumed, including materials in sub-assemblies.

SAP PEO and SAP PP

The integration of SAP PEO in S/4HANA does not mean that it replaces classic SAP Production Planning, but rather that it must be thought of as a supplement. All Production planning functionalities such as BOM and routing explosion or order creation and release are still available and act completely homogeneously with the new applications and functions.

The activities are mainly used for planning, scheduling and costing, whereas the newly introduced activities are used in store floor execution. The production of serialized assemblies also represents a special feature. Here, Order Management and Order Control as modules of the PO offer extended track and trace functionalities in the context of serialization.

The well-known worklist, which in industrial companies is often created in SAP with the help of Excel or Z-Tools, can now be called up directly in SAP PEO. The new solution differentiates between personalized work queues for workers or workstation/resource-based queues. Backlogs, defects and buyoffs can be initiated directly from the UI (Perform Operation Activity) created for the worker.

All information accumulated during the execution of activities, as well as all backlogs, defects and buyoffs are documented in the action log - at serial number granularity. This increases process reliability and avoids expensive rework. For the entire range of functions, in addition to classic GUI transactions, the system offers a variety of user-friendly applications in the SAP Fiori Launchpad.

On this basis, it is possible to implement and establish end-to-end processes with seamless traceability with regard to engineering changes. This provides designers, planners, production controllers, work planners and workers with a platform that accesses the same database.

Our services for you

- Workshop for end-to-end process definition and its validation

- Implementation and consulting of the SAP PEO solution

- Implementation of customized and customer-specific enhancements

- Targeted error source analysis for better staff planning

- Hypercare and go-live support

- Optimization of master data quality

- Creation of clear processes

- Concept for better production control overview